Background

Statius, have worked for key components of the international and multi-billion turnover engineering company GEA for in excess of 20 years. The first assignment having been secured with Morris & Young (M&Y) in 1994.

In 2014 one of the original Morris and Young contacts made a call to Statius asking if we would be interested in helping with the creation and certification of a management system for a new, centrally based, manufacturing facility, the European Skid Centre (ESC).

The remit of the ESC was to create and develop a range of standard refrigeration “skids”, which would also need to comply with the Pressure Equipment Regulations. These would then be supplied to the various sister companies delivering refrigeration solutions in each of the nation states throughout Europe.

The objectives of the new ESC were to:

• Create a range of standard refrigeration products and in doing so;

o Significantly reduce the new product development timescales

o Significantly reduce product build times and costs

o Significantly improve manufacturing margins

o Free up expensive local engineering talent for higher margin activities

The creation of the ESC was a major departure for the Group with the creation of a truly international team drawn from various corners of the international GEA operation.

The approach and the solution

Given that the team were new, a deliberate decision was taken to use the implementation of the management system process to:

• Align ESC goals and objectives against upstream corporate objectives and national company objectives downstream

• Align the team to the goals and objectives of the Centre

• Create processes and procedures that related not to the current “as is” situation but the anticipated future “to be” situation. This would provide an ideal to “aim at”

• Link processes to key performance indicators

A key objective behind the development of the management system was that it would need to integrate upstream with the activities of the corporate technical centres and down-stream with the activities of the practices employed by the European sister companies. However, there were still “tensions” with the concept and it still needed “selling” to the sister companies. Consequently, it was decided that the first step would be to undertake a workshop with the senior team detailing how the ESC processes meshed with the sister company processes and critically to define an answer to what was identified by the MD “The Killer Question” …which was;

How would the ESC add real value for these sister companies?

A statement of “purpose” was devised which articulated the “benefits” and “capabilities” the ESC would provide to the sister companies. The value delivered was defined as being:

“To grow your business and improve your profitability by providing proven, modular, competitive designs allowing you to redirect your resources to break into new markets”

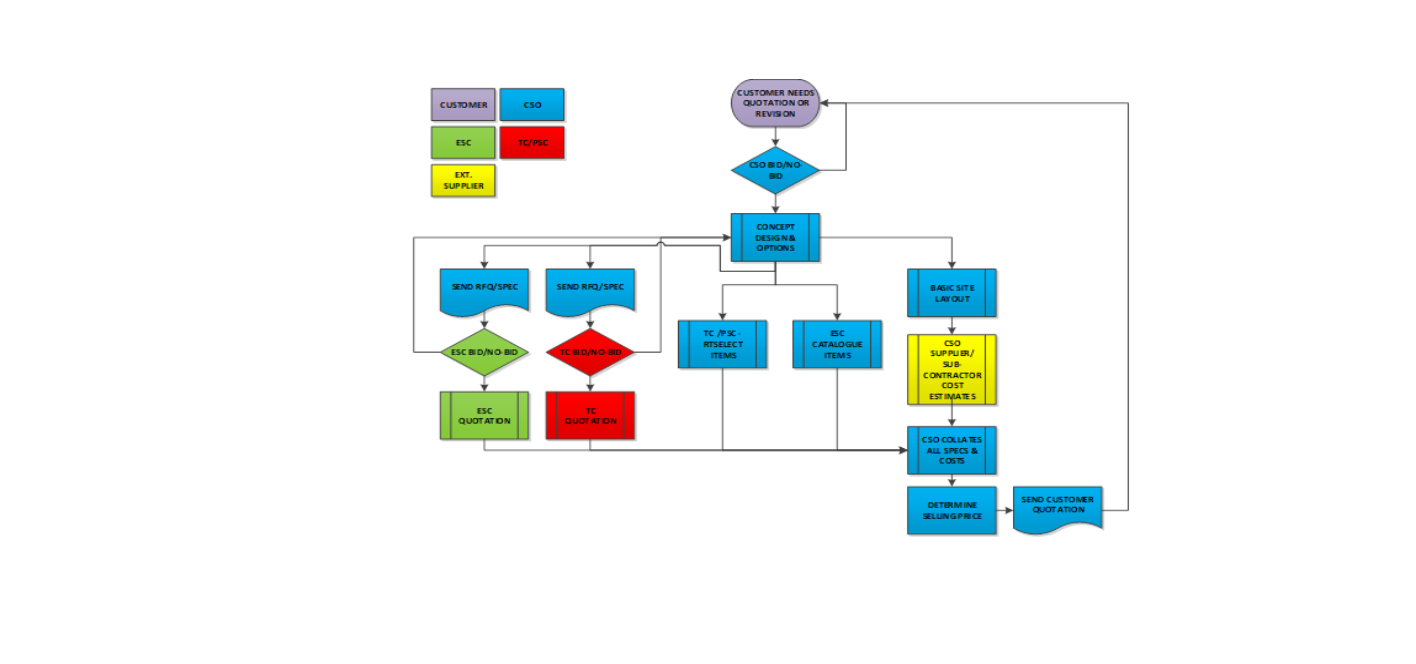

In addition, a diagram showing how the ESC processes interact upstream with the sister companies throughout Europe and downstream with the Technical Centres’ was also developed and has been reproduced below.

Mapping external relationships and processes

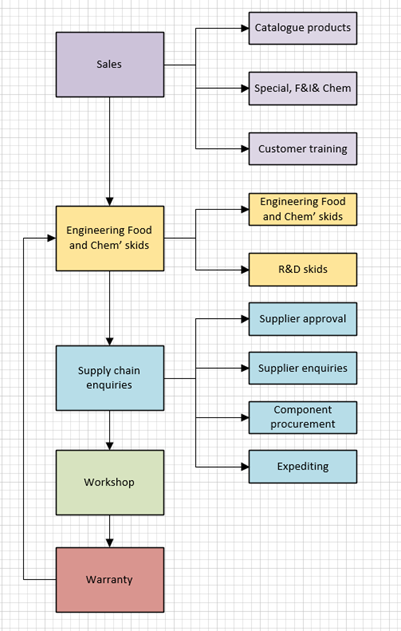

Once the external interactions with the sister companies and technical centres had been documented and understood, specifically in relation to how the company was to deliver value, the second stage in the process was to derive a diagram showing how the key internal processes interacted with the new ESC structures that were being developed from the ground up.

A series of workshops were undertaken with the leadership team and all of the value adding processes, from sales to warranty, were mapped out at the top level as seen from the following diagram.

Mapping internal relationships and processes

This second diagram showing the key internal ESC processes, and how they interact, was also developed prior to developing the lower level process flow charts, which outline the detail of how the specific activities undertaken interact with one another.

At the lowest process level a series of workshops and meetings at which the leadership team and key staff took an iterative approach to map out the detail of these key internal processes and how they differed from the ideal were held and over a six-month period.

Each of these individual processes was then mapped to define the flow of work through the company and how, at a lower level, they interacted with one another.

Processes and procedures were developed for each of the above key areas defining:

• Key performance indicators

• Responsibilities

• Links to other control arrangements

As part of the process the different views on current and ideal processes were collated and prioritised into an action plan which was used, along with the relationship between the KPI’s and the documented processes, to drive future change and improvement activities.

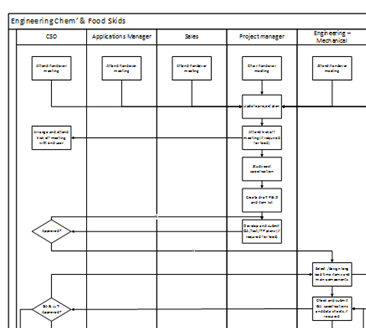

Lowest level flowcharts

The workshops fleshed out the detail flowcharts at the lowest level showing:

• Relationships and interactions with different staff and processes

• Relationships with other documentation (specifications, datasheets, calculations, testing arrangements ….)

A sample of one of the engineering flowcharts has been reproduced below

The workshops fleshed out the detail flowcharts at the lowest level showing:

• Relationships and interactions with different staff and processes

• Relationships with other documentation (specifications, datasheets, calculations, testing arrangements ….)

A sample of one of the engineering flowcharts has been reproduced below

Comments

Some of the comments made by the senior team during the project are telling:

• “We were taking 5-6 years to bring a new product to market and by that time the need has changed”

• “What we are really trying to so is standardise the solutions offered”

• As a new organisation “We are writing procedures today because we actually need them tomorrow”

The Benefits

“Statius provided us with a great service and a great process; staff were engaged, objectives were defined, future proofed processes were written, KPI’s were established an improvement plan was created and executed and registration was obtained at the first attempt”

Managing Director GEA European Skid Centre

Benefits included:

• The alignment of the objectives and aspirations of both internal and external stakeholders

• The management team were significantly better aligned to the goals of the centre

• More structure was developed improving communications with European sister companies and the technical centres

• A defined set of key performance indicators were established and linked to processes and practices

• Real buy in to developing robust and useful processes

• Significantly improved rigor was imposed on the process improving efficiency and effectiveness

• A comprehensive list of improvement projects was developed

• An agreed set of critical calculations, terms and conditions, forms and templates were agreed with the sister companies

• Registration at the first attempt