The problem

The client had been registered to ISO 9001 for a number of years but the system, developed by a consultant with a “big company” focus, was of such byzantine complexity that it was neither understood nor useful. It did not reflect the way the work worked.

The MD, and her business coach, wanted a system that could be used as a platform for “best practice” on which the company could:

• Significantly increase sales

• Take on larger and more complex projects

• Get buy in from all staff to:

o Company goals, aims and ambitions

o Documented and codified practices and procedures

• Use to drive the change and productivity improvements that would be necessary to achieve the above

The client

The 32-person company has been developing and making bespoke textile solutions for military & commercial applications for over 35 years. The company had gone though various ownership incarnations and the current owner, and her business coach, saw significant opportunities in the marketplace, but they needed systems and processes that were both understood, and robust, in order to make the changes necessary to exploit the commercial opportunities

The approach and the solution

The initial issue was the imminent external assessment, and the fact that “nothing has been done with the system for a year!” Actions taken included:

• A “quick and dirty” audit against the clauses of the standard

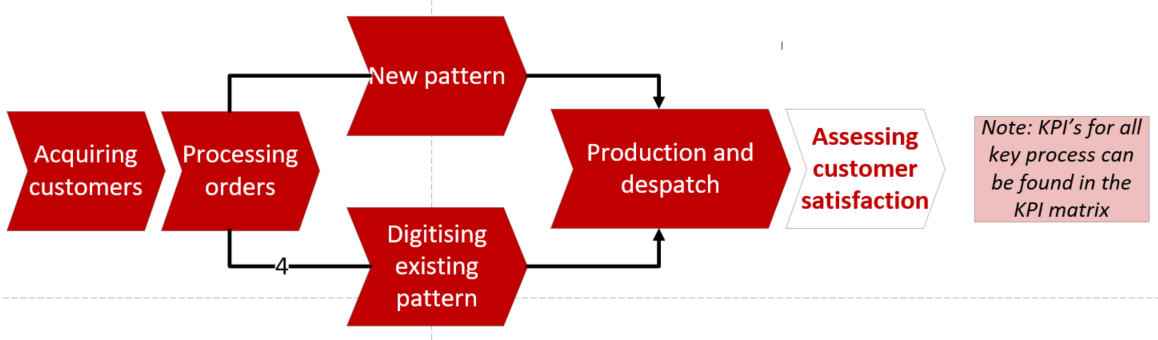

• A senior management workshop to develop a map of the core activities – a flowchart showing the core processes and how they delivered value to the client

The Core Activity Map showing how the work works to deliver value

• Developing a plan to show how the system would be re-developed so it was:

o Simple to understand

o Easy to follow

o Capable of delivering on the management’s objectives

A management review which documented the plan with timelines and the route forward

The outcome

The whole culture has changed, ISO now no longer “scares us”, the systems reflect what we do and all staff are involved in driving the business and the system forward…

Managing Director

Kay Smith

The external audit was passed with flying colours on the proviso that the work outlined in the plan was completed in a timely manner.

Following the external assessment, it was time for the real work:

• The existing processes and procedures were reviewed against the core activity map, unnecessary procedures were jettisoned, overlapping procedures were merged and complex procedures simplified, all using the company’s language and terminology.

• The number of procedures were reduced from 35 to 19

• Flowcharts were developed for all core and supporting processes each with their own KPI’s and links to the KPI matrix in order to measure and drive change focused on improving the cash to cash cycle

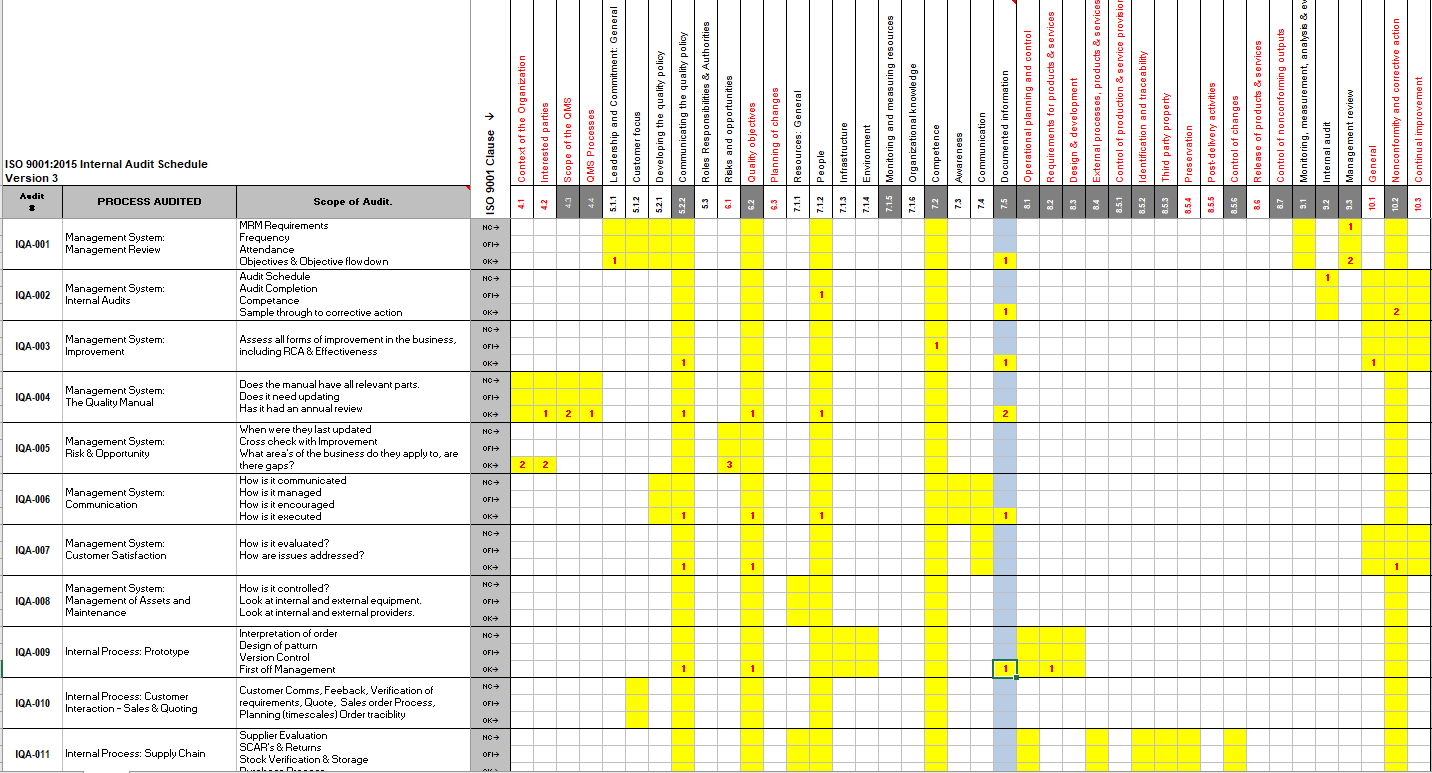

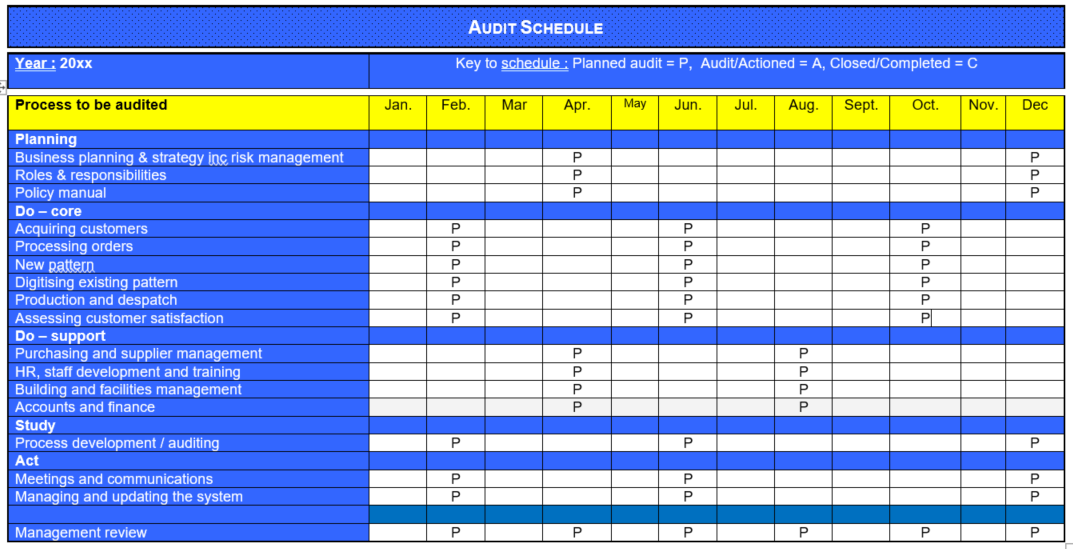

• The audit schedule, possibly the most complex we’d ever seen, partial copy below, was drastically simplified from a 52 row x 74 column excel spread sheet to a single page 13 x 10 table

Original (partial) audit schedule – showing about 1/4 of the entire schedule

New complete schedule. The non-conformance processes were streamlined and developed to include costing which provided a greater focus for learning and and improvement.