Tools to make you THINK differently about your business

Have you ever thought about the extensive amount of time and effort that companies put into changing things but despite this, nothing much seems to actually improve?

Fortunately, there is a deceptively simple structure for using KPI’s to drive learning. The inventor, Dr Shewhart used the model for improving the production of telephones. It’s pioneer, Dr Deming, developed the model and used it to improve the American census operations. Since then the model has been used by numerous companies, notably Ford, Motorola and Toyota. From time-to-time the model gets re-invented and re-badged, but I like the original model. Interestingly, and intriguingly, people (including myself) think that they understand it in minutes, and they do, and they can apply it to make real significant and lasting change, but, also after using the model for years, they also, like me, think they might understand it fully some day!

Time and time again we come across people and companies that invest a tremendous amount of effort in changing processes, practices, procedures… and even people, in order to seek elusive improvements. The question we usually ask, which often stumps them, is “How do you know…for sure, that the change has actually led to an improvement?”. The intentions are right but they rarely apply KPIs that allow them to know, for sure, whether or not the changes made, are actually improvements.

At the other extreme, we come across companies knee deep in KPIs and data; metrics are recorded at every available opportunity. The KPI data is revered, cherished even. But nothing is done with it! No action is taken! Sacrilege!

But where do you start?

As I think we’ve said before, start from the outside and work backwards…The initial focus should be on what is it that the customer actually wants. That’s the subject of a different blog, but assuming that’s accounted for, what’s next?

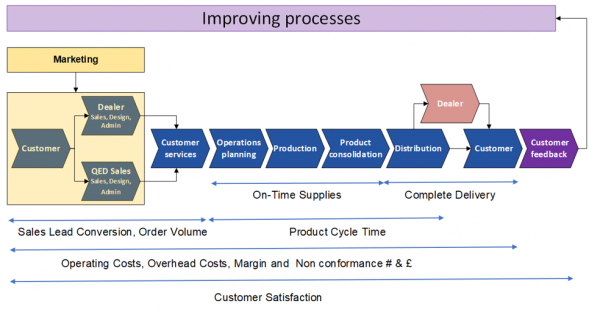

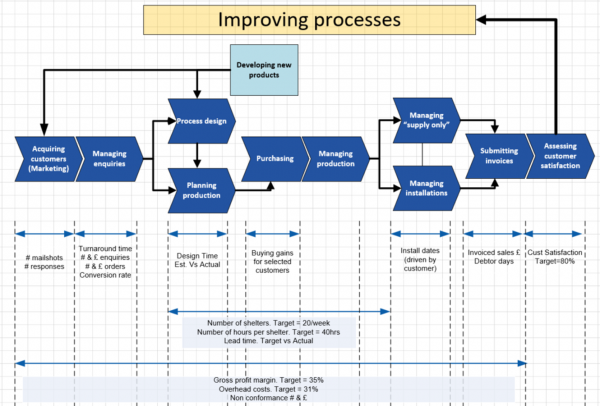

The key is to understand how your work works; what is the logic and sequence of the activities you undertake to deliver value to your client base? This we’d call a Core Activity Map which needs to be married to your KPIs in order to know the change is an improvement. Although often similar, for companies in the same sector, this needs to be a completely individual map of your processes. A more comprehensive explanation can be found in an earlier blog, However, for ease we have reproduced a couple of Core Activity Maps showing a sample of their associated KPIs, below:

Furniture company Core Activity Map and KPIs

Manufacturing company Core Activity Map and KPIs

So, now we have some KPIs…how do we use them?

The structure of learning

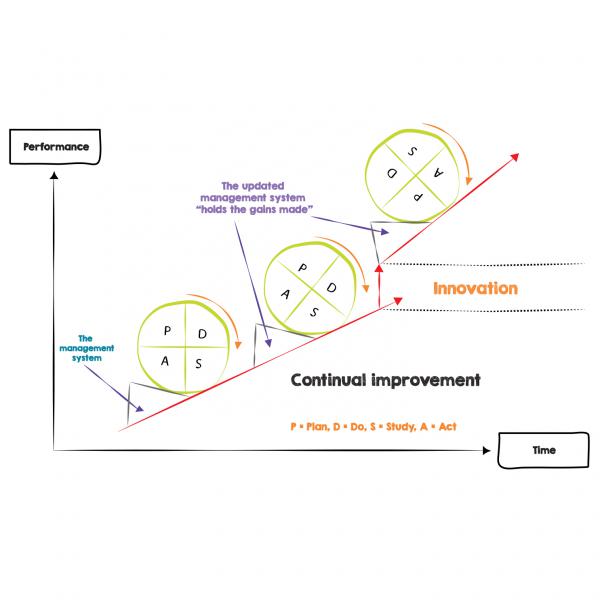

The diagram below shows the structure; the Shewhart Plan, Do, Study, Act (PDSA) model for learning, which provides a foundation for systematic and continual improvement. It is an improvement process that involves an ongoing cycle of activities. After Act, it begins anew: Plan again, Do again, Study again, Act again – an unending cycle of learning, evaluating, and working on KPI’s processes and capturing benefits.

In more detail, the PDSA cycle comprises:

- Plan – The process is first studied to obtain a detailed understanding of the current ‘As Is’ situation. The question being asked is “how well is the company performing against chosen KPIs?” Then, based on an understanding of the organisation’s purpose, its customers’ requirements and current and past KPI data (process measures) an improvement plan is formulated.

- Do – The changes are made as detailed in the improvement plan. A pilot programme on a small scale is recommended as a first step, if possible. (Large, unstudied changes can lead to large consequences – good and bad!)

- Study – The KPI results obtained are compared with the desired KPI results in order to learn from them. This is where we need data; data provides the proof that a change is an improvement. And for this we rely on the Process Prediction Chart™.

- Act – Take advantage of what you have learned. Decide what you will try next. The question at this point is: Do you continue to improve this particular process? If so, go around the cycle again. If not, standardise the new process, for instance, by locking the gain into any documented operating procedures or Book of Best Practice. Then plan again, but for a different improvement project.

As can be seen from the diagram, sitting behind the PDSA wheel is a wedge, essentially the organisation’s documented management system; the organisation’s standing orders, operating instructions or perhaps an ISO registered system. Regardless, training, in the new improved processes needs to be provided and communicated and the documented management system, or Book of Best Practice, must be updated to reflect these new processes and hold the gains made.

The benefits of the model are that it is:

• Simple and flexible

• Can be adapted to pretty much any situation.

Conclusion `

Using the right KPIs and the PDSA model is the essence of management; making sure the work gets done today AND developing better ways to undertake the same work tomorrow.

The PDSA cycle represents a robust and scientific approach to learning; it drives interdependence through a team work approach; it drives teams to innovate, generate new ideas on how projects and processes should work and it provides a formalised structure for learning and for knowing that a change has led to an improvement. Change and improvement are not the same thing.

The PDSA framework is a lever to drive performance improvement; for staff to formulate theories, test them on a small scale and then assess them; PDSA provides a trigger for structured creativity. As noted in Brian Joiners excellent book 4th Generation management “It is by intuition that we discover but by logic and data that we prove”.

The right KPIs and the PDSA model provides a robust framework for learning, improving and driving quantifiable change.

Related tools and ideas

Recommended references

- Dragon Slaying: a better way to manage by Mark Woods; email mwoods@statius.co.uk to receive your free copy

Downloadable resources

To find out how Statius can help you deliver:

• Better strategies

• Better systems

• Better measurement and

• Engaged people delivering

• Better results

Call us now on 0208 460 3345 or email sales@statius.co.uk

Comments are closed